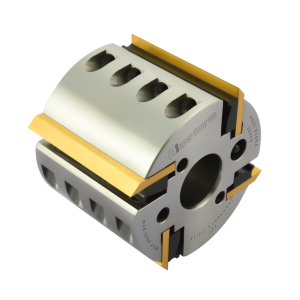

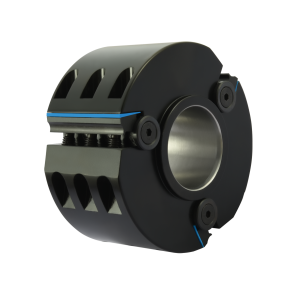

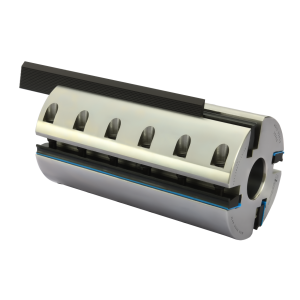

With high-quality materials, exquisite manufacturing technology, advanced CNC equipment, and thorough online and offline inspection, SuperSource offers cutterheads that are highly precise, reliable, cost-effective, and easy to operate. Used together with our interchangeable and grindable corrugated knives that far exceed the most stringent EU OEM standards, our cutterhead products can be operated at speeds up to 8,000 rpm and are competent for most wood profiling and surface processing applications.

Our cutterhead products are divided into straight bore cutter heads and hydraulic locking cutter heads in terms of the bore type, and are compatible with both corrugated knives and planer knives. In addition to the regular products presented in the catalogue, custom features and design (i.e., with customer choice of bore size, cutting angles, knife pockets, pocket depth, etc.) can be fulfilled upon request.