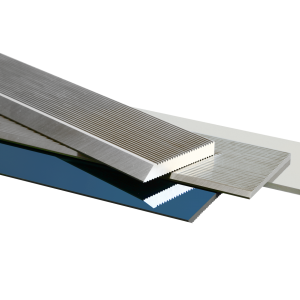

Our customers around the world have recognized the woodworking knives of SuperSource Tooling for their reliability and variability for decades. SuperSource Tooling is committed to providing the best user experience through advanced processing technologies, specialized manufacturing equipment, and a comprehensive quality management system. We offer a wide range of woodworking cutting tools with various materials and dimensions to meet customers’ needs for processing all types of wood and wood-derived materials.

Our woodworking knives consist of planer knives, quick-lock planer knives, corrugated knives, SuperHelic™ knives, Williams & Hussey (W&H) knives, and other custom knives. We offer not only common base materials, such as D2 high-carbon high-chromium steel, various high-speed steel (HSS) materials, TCT inlaid, and solid carbides, but also a variety of coating applications such as WR, BNv, ER+, etc. Our world-class quality woodworking cutting tools, which provide a much finer cutting finish and longer service life than other similar products in the market, have been sold globally and have won unanimous praise from all customers.