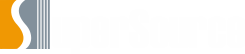

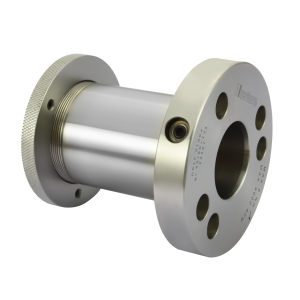

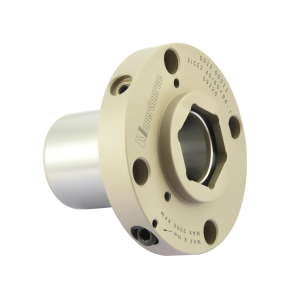

SuperSource hydro-lock sleeves are a cost-effective solution for wood processing applications that require quick fastening and high precision self-centering of tools. The principle is to use the liquid medium to transmit the expansion force, between the inner ring of the expansion sleeve and the shaft, and between the outer ring and the hub. The generated surface tension between the two parts ensures the high-precision automatic centering and locking of the hub and the shaft. We offer two types of hydro-lock sleeves depending on the pressurizing modes, pressurized through Allen screws or a high-pressure grease pump. We provide various bolt connection setting to ensure compatibility of our product with the most machine in the market.

To meet the diversified market demand, we have continued introducing new products. We successively launched various high-end products such as SB3, SC3, AIL, and SQS2. With advanced processing, testing, and production management system, our products lead the industry in critical technical parameters such as concentricity and radial runout and have a cost-effective advantage over similar products in the market. Besides our standard products, we also offer a comprehensive range of custom products to meet any special requirements.