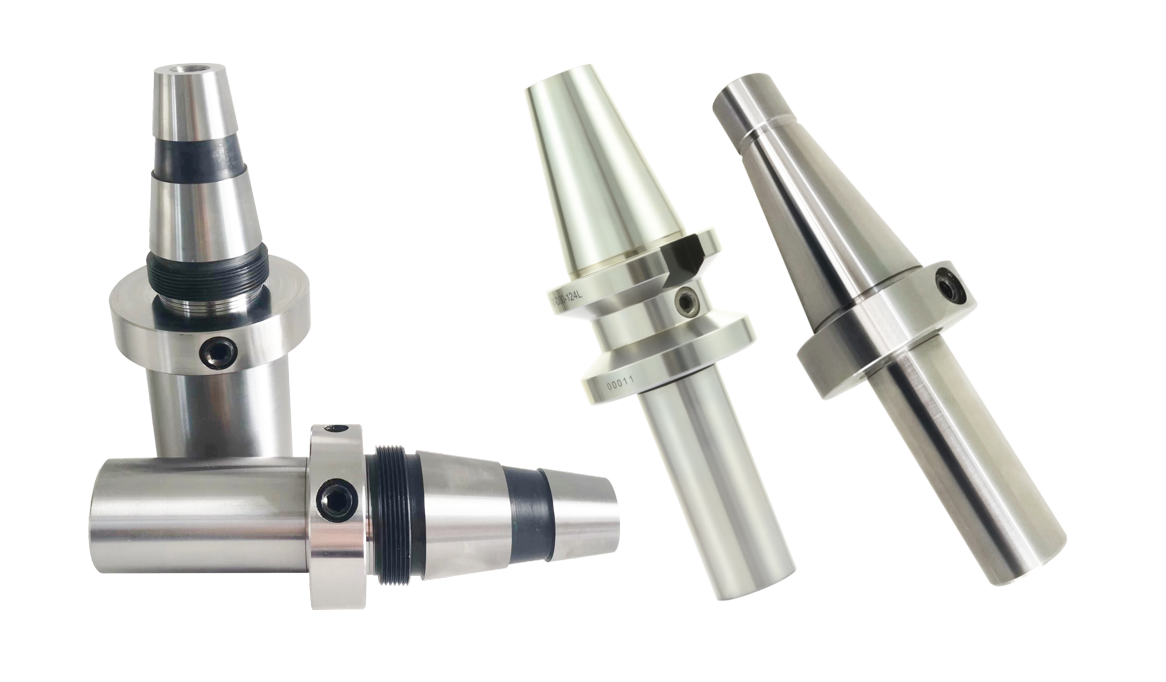

At SuperSource Tooling, we understand that sharpening saw blades, planer knives, profile tooling, and other cutting implements isn't just maintenance—it's a process that demands precision, consistency, and safety. That's why a custom hydraulic tool holder makes an exceptional, specialized fixture for these sharpening tasks. Below, we explore why this toolholder solution transforms sharpening setups.

Why Hydraulic Tool Holders Excel in Sharpening Fixtures

Exceptionally Consistent Clamping Pressure: Hydraulic holders use an internal bladder filled with fluid, creating uniform radial force around the tool shank—ideal for holding saw blades and knives firmly during sharpening.

Sub-Micron Runout Accuracy: Many hydraulic chucks achieve ≤ 0.0001″ (2.5 µm) runout at 3× diameter, ensuring tools remain concentric—critical for profiling tools and saw blades.

Speedy & Secure Adjustments: Sharpening setups often require repositioning tools at precise angles. Hydraulic holders clamp or release quickly using a single hex screw—safe and efficient.

Compatible with Most Spindle Interfaces in Market, Enhancing Overall Machine Efficiency

From common BT and NT setups to advanced high-speed HSK machining centers, SuperSource Tooling provides custom hydraulic holders tailored to your spindle interface—and engineered for perfection. Expect unmatched precision, quick tool changes, comprehensive interface compatibility, and support designed to enhance uptime and profitability.

Ready to upgrade your tooling? Contact us for a custom hydraulic holder consultation—specify your spindle interface, tool types, and cut conditions. We'll deliver holders that plug right in and elevate every operation.